Hycroft Mining drone survey technology is transforming how geologists find precious metals underground. In mining, one of the biggest challenges is finding where gold and silver are concentrated deep beneath the surface. Traditional survey tools often cannot reach areas hidden beneath steep pit walls or lying thousands of feet below the surface. That leaves possible rich deposits undiscovered, slowing progress and driving up costs. Hycroft Mining Holding Corporation, headquartered in Winnemucca, Nevada, approached the problem in a new way.

The company owns the Hycroft Mine, one of the largest gold and silver deposits in North America. To search deeper than traditional methods allowed, Hycroft used a heavy-lift drone to carry survey lines over pit walls that were previously inaccessible. The drone technology is allowing the company to explore in great detail one of Nevada’s richest gold and silver sites in ways that were never possible before.

Drone Survey At Brimstone Site

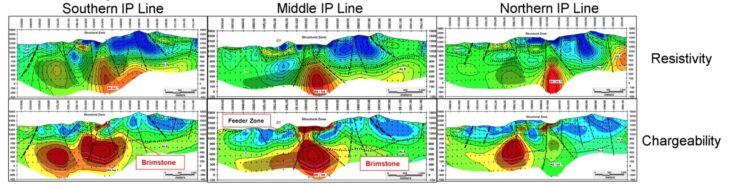

Three IP Lines pictured in Figure 1 showing Brimstone geophysics and modeled structure based on mapping and drilling.

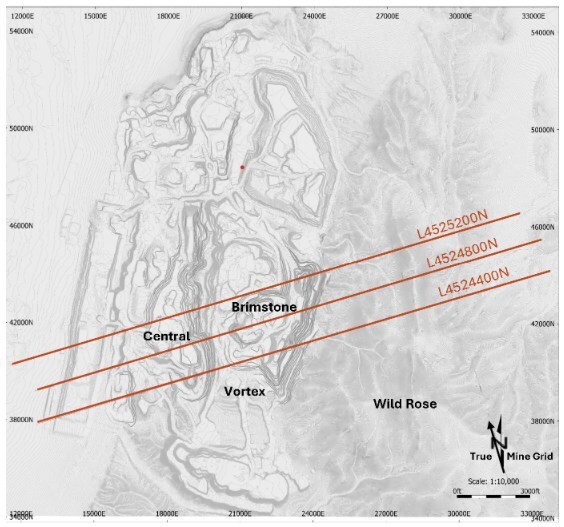

The company announced new results from its Brimstone area, part of the Hycroft Mine near Winnemucca, showing evidence of a potential feeder system that could explain the high-grade silver already discovered there. By doing this, geologists were able to gather data from more than half a mile below the surface. The results revealed a large underground structure measuring about 2,100 feet long and 1,400 feet wide at a depth of roughly 1,600 feet. This structure could point to a feeder system supplying the high-grade silver found at the site.

The decision to use drones proved to be a turning point. Instead of sending workers into dangerous areas or setting up costly ground equipment, the drone placed the survey lines in minutes to carry out an Induced Polarization (IP) survey. This method measures how underground rock responds to electrical current, which helps geologists detect mineral-rich zones without drilling.

“I am excited to announce the results from the IP survey, which indicates that Brimstone’s mineral endowment may extend well beyond the impressive high-grade drill results from 2024,” said Alex Davidson, Hycroft’s Vice President of Exploration.

He added that using “a heavy lift drone to fly the IP wire” was a major innovation for the project.

Partnership With Zonge International

Hycroft worked with Zonge International Geophysical Services, a geophysical survey company headquartered in Tucson, Arizona, to carry out the IP survey at its Brimstone site. Founded in 1972 by Kenneth L. Zonge, the company specializes in providing geophysical services and equipment for mineral exploration, environmental studies, and engineering projects.

Hycroft contracted Zonge for their expertise in designing and executing complex surveys in difficult terrain, allowing the heavy-lift drone to safely deploy IP survey lines along steep pit walls. Zonge’s experience ensures accurate data collection while minimizing risk to personnel and equipment. “Zonge geophysical data acquisition systems include power source, specialty cables, processing software, and peripheral equipment for your intended purpose,” the company’s website states. “Each system is capable of multiple survey methods and acquisition parameters without compromising data quality or collection efficiency.” This suite of tools now includes drones, such as the heavy-lift drones used to conduct the IP survey at Hycroft’s Brimstone site.

The Bigger Picture: Drones In Mining

Drone use in mining is part of a larger trend. Around the world, companies are relying on aerial platforms to see what lies beneath the surface. Modern drones can be fitted with tools like radar, magnetometers, and high-resolution cameras that capture detailed images. In Hycroft’s case, drones also carry and place IP wires in sensitive locations. They can scan areas too steep or remote for crews to reach while reducing risks to workers. The technology also cuts down the time it takes to run surveys. What used to take years of manual work on the ground can now often be completed in a matter of months.

Geophysics lines through Brimstone. Lines are due east-west

Drones allow experts to gather data safely and quickly in places that were once off limits. The information collected gives miners a clearer picture of what lies underground before drilling begins, saving both time and money. Ultimately, the drone survey is the key to allowing Hycroft to plan for the future of its mining operations.“As we advance to the next phase, we’re driven by a clear vision,” said Hycroft President and CEO Diane Garrett, “to transform this asset into a cornerstone of future supply, developed responsibly and with purpose for the benefit of all our shareholders. The culmination of our work comes at a very exciting time with gold and silver at all-time highs, and the U.S. Government recently declaring silver as a critical mineral.”

The Hycroft Mining drone survey demonstrates how advanced aerial technology can unlock new mineral resources while reducing costs and risks. As mining companies continue to adopt drones, the industry is likely to see more efficient exploration and safer operations in the years to come.

|