Drone battery technology is driving a new phase of innovation in the drone industry. The drone revolution has skyrocketed over the last decade in ways few anticipated. What began largely as hobbyist quadcopters and basic aerial photography has evolved into a vast range of industrial, commercial, agricultural, environmental, and defense applications. Drones now map farmlands using multispectral sensors to optimize crop yields, inspect oil rigs and power lines in remote areas, deliver medical supplies to rural regions, monitor wildlife and track deforestation, and support disaster relief operations. In film and media, drones capture sweeping aerial shots once only possible with helicopters. In logistics, they are increasingly considered for rapid last-mile delivery. In public safety, they assist first responders by surveying damage after hurricanes, floods, or wildfires. Across industries, drones have transformed how tasks are performed, offering speed, precision, and access to areas previously considered unreachable.

The Challenge Of Limited Flight Time

Even though drones are revolutionizing the world, they all tend to share one major flaw: limited flight time. This limitation exists because a drone’s size and endurance must be matched to the size and capacity of its battery or other power source. Heavier batteries add weight, which increases the energy needed for flight, creating a tradeoff between payload, battery size, and operational efficiency. Most commercial or off-the-shelf drones have flight times averaging between twenty and thirty minutes under normal conditions. Even enterprise models, optimized for industrial operations, rarely exceed fifty to sixty minutes when carrying meaningful sensors or equipment. Designers and engineers must balance flight duration against payload, wind conditions, altitude, and safety considerations, making long-duration missions particularly challenging.

Innovations In Drone Battery Technology

Because limited flight time is such a universal issue, new sectors of the drone industry have emerged specifically to solve this problem. Companies are developing advanced battery chemistries, hybrid propulsion systems, fuel cells, tethered drone options, and even solar augmentation for drones. Engineers are exploring lighter materials, more efficient motors, and smarter power management systems to maximize energy use. Battery manufacturers and material scientists are increasingly partnering with drone companies to develop energy storage solutions that extend flight duration without compromising payload or safety. The industry is shifting from accepting limited flight time as a constraint to treating it as a primary area of innovation.

NEO Battery Materials And Intelligent Drone Systems Deal

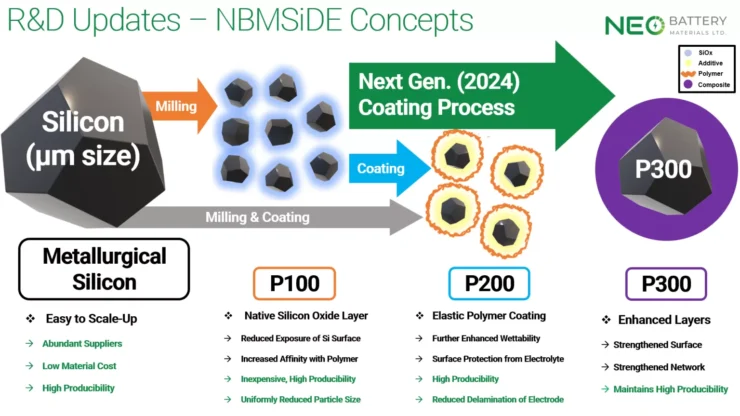

One example of this shift is embodied by NEO Battery Materials Ltd, which in September 2025 secured a CAD $4.5 million purchase order and Joint Development Agreement with an Asian drone and UAV manufacturer. NEO, founded in 2006 and headquartered in Vancouver, Canada, is a battery materials company specializing in silicon-based anode technologies to improve lithium-ion battery performance. The company has focused on applications across electric vehicles, energy storage, and aerospace. Their new partner, Intelligent Drone Systems Co. of South Korea, is a leading manufacturer of unmanned aircraft designed for both civilian and defense applications. The company has gained recognition for incorporating advanced flight control systems that leverage artificial intelligence to improve mission planning and operational reliability.

Silicon-Enhanced Drone Battery Solutions

The deal between the two companies will produce two silicon-enhanced battery products tailored to the drone manufacturer’s systems. The first model, the P-200, is being developed for short-duration missions in defense and tactical operations.

The second, the P-300N, will focus on industrial and surveillance applications where extended flight times and heavier payloads are required. Mr. Spencer Huh, President and CEO of NEO, stated that these batteries will deliver:

“Industry-leading capacities, safety-reinforced power output, and overall weight reduction to enhance flight time, payload capacity, and mission operability.”

He adds that under the Joint Development Agreement, they are targeting high energy density exceeding 350 watt-hours per kilogram, representing “more than a 40 to 59 percent increase compared to conventional drone batteries of 220 to 250 Wh/kg.” These improvements have the potential to allow drones to remain airborne longer while carrying heavier sensors or payloads, reducing the need for frequent battery swaps.

Impact On Drone Operations

Extended endurance could allow for longer agricultural surveys, more persistent infrastructure inspections, and continuous monitoring of disaster zones without interruption, for example. According to NEO’s website, the company’s mission is “to help accelerate the mass adoption of electric vehicles through low-cost, long-running, and fast-charging silicon anode materials.” This focus on efficiency, affordability, and high energy density signals a new phase of drone innovation where power storage is treated as central to capability rather than a peripheral concern.

|